Hot Melt Equipment

Adhesive & Packaging Systems provide a wide range of hot melt equipment and cold glue systems, replacement parts, installation, repairs, and rentals. We’ve partnered with ITW Dynatec to offer a complete range of adhesive application equipment. Below are some of our most popular products we have to offer. If you are unsure about the melter you need, please check out the comparison chart to get a full range of melters we have to offer. If you have any questions about the products, please contact us.

Replacement Parts & Units

We have supplied high-quality replacement parts and units to customers worldwide since 1970. You’ll find all of our products are designed to meet all your needs, including your budget. Our aftermarket parts, equipment and complete systems are designed to work with all major OEM products including:

- Nordson®

- Slautterback®

- ITW/LTI®

- And More!

Dynamini™ Series

DYNAMINI™ hot melt adhesive supply units provide exceptional value in a small hot melt unit which has been designed for optimal performance, reliability and simplified daily operation. The patented melt-on-demand hopper with 7 year warranty standard. Benefits of the Melt-on-Demand Hopper:

DYNAMINI™ hot melt adhesive supply units provide exceptional value in a small hot melt unit which has been designed for optimal performance, reliability and simplified daily operation. The patented melt-on-demand hopper with 7 year warranty standard. Benefits of the Melt-on-Demand Hopper:

- Less Energy Consumption

- Operator Safety

- Faster System Ready

- Adhesive Degradation is Greatly Reduced

- Reduced Maintenance

Dynamelt™ S Series

The Dynamelt™ system provides accurate, proportionate temperature control for the hopper, hoses and applicators. Sequential heating delays may be programmed for turn-on of the hoses and heads. Available in a Piston or Gear pump control. Benefits of the Dynamelt S Series:

The Dynamelt™ system provides accurate, proportionate temperature control for the hopper, hoses and applicators. Sequential heating delays may be programmed for turn-on of the hoses and heads. Available in a Piston or Gear pump control. Benefits of the Dynamelt S Series:

- 15x More Filter Surface Area

- Finger Safe Electronics

- Covered Manifold

- Easy Installation, Compact Footprint

- Easy-to-Read, Moveable Display Panel

Dynamini™ & DGII™ Hand Applicator

DYNAMINI™ hot melt adhesive supply units provide exceptional value in a small hot melt unit which has been designed for optimal performance, reliability and simplified daily operation. The DG II™ is designed for flexibility and can be used in various configurations depending upon your application. A configured system comes with:

DYNAMINI™ hot melt adhesive supply units provide exceptional value in a small hot melt unit which has been designed for optimal performance, reliability and simplified daily operation. The DG II™ is designed for flexibility and can be used in various configurations depending upon your application. A configured system comes with:

- Dynamini™ Adhesive Supply Unit

- Hot-Melt Adhesive Hose

- DGII™ Hand Applicator

- Easy Installation, Compact Footprint

- Bead Nozzle for the Bead DGII™ or

- Swirl Adapter, Nozzle and Cap for the Swirl DGII™

- Swirl Air Kit for the Swirl DGII™

DynaFlex™ Hoses

Hot melt adhesive supply hoses are electrically-heated, flexible conduits designed for the transfer of hot-melt material from an adhesive supply unit (ASU) to an applicator (head or handgun). The Dynaflex Hose can accommodate a bend radius as

Hot melt adhesive supply hoses are electrically-heated, flexible conduits designed for the transfer of hot-melt material from an adhesive supply unit (ASU) to an applicator (head or handgun). The Dynaflex Hose can accommodate a bend radius as

small as 8 inches. Customization includes:

- Optional Nylon Strap

- 45 and 90 Degree Fitting Configuration

- Abrasion Resistant and Washdown Resistant

- Hose Hanger, Ridged

Pattern Controllers

The Pattern Controller is one component of an adhesive application system consisting of a hot-melt unit, cold glue pressure vessel or cold glue pump, adhesive hoses and applicator heads. The controller can be used for hot-melt or cold glue application.

The Pattern Controller is one component of an adhesive application system consisting of a hot-melt unit, cold glue pressure vessel or cold glue pump, adhesive hoses and applicator heads. The controller can be used for hot-melt or cold glue application.

Adhesive Applicators

We offer a wide range of adhesive applicator heads including glue guns, slot, bead, and adhesive spray technologies to meet your company’s application needs.

We offer a wide range of adhesive applicator heads including glue guns, slot, bead, and adhesive spray technologies to meet your company’s application needs.

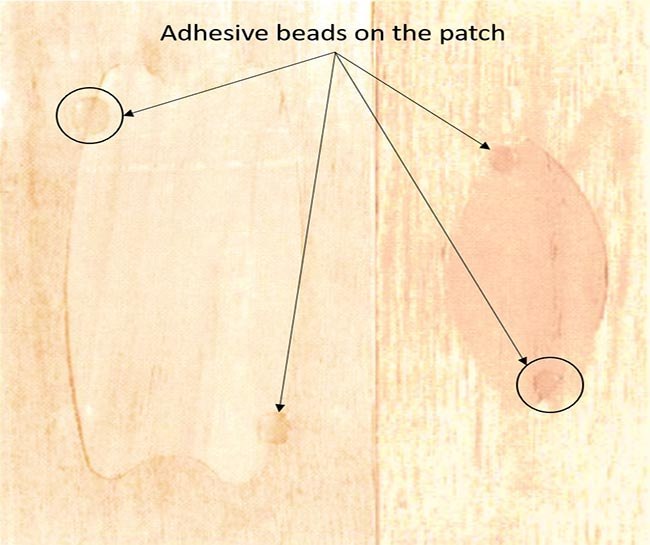

Plypatch

PLYPATCH was developed by Adhesive & Packaging Systems to reduce patch fallout and reduce production costs by increasing production output. Fallout is reduced by 80% while panel falldown decreases from 4% to 1.6%. Plypatch systems are installed directly on patchers and the adhesive is automatically applied when the patch machine is cycled.

PLYPATCH was developed by Adhesive & Packaging Systems to reduce patch fallout and reduce production costs by increasing production output. Fallout is reduced by 80% while panel falldown decreases from 4% to 1.6%. Plypatch systems are installed directly on patchers and the adhesive is automatically applied when the patch machine is cycled.

Veneer Composers

Veneer Composers are used to compose various wood species and veneer sizes and thickness into quality plywood core with a minimum of waste. Composed veneer improves plywood quality, reduces labor, wood and glue usage thereby reducing overall production costs.

Veneer Composers are used to compose various wood species and veneer sizes and thickness into quality plywood core with a minimum of waste. Composed veneer improves plywood quality, reduces labor, wood and glue usage thereby reducing overall production costs.