5 Tips to reduce char buildup in hot melt glue units

Let’s just get this out there: adhesive char is not something you want to build up inside your hot melt system.

Adhesive char is the residue from the hot melt glue. Over time, it forms and builds up inside an idle hot melt system that is on and heated, but not actively in use. Char can affect how quickly and easily glue moves through hoses. As it begins to build up, it creates the potential for future clogs, especially as char breaks away from the hose walls and flows through the system. If no action is taken to prevent char, or, to clean it out when it becomes apparently, quality can suffer due to clogs, uneven application of adhesives, even degradation inside the tanks that is caused by the buildup of char.

Depending on the pot life of specific hot melt glue types, the time it takes for char to build will vary. There are things that you can do to reduce the likelihood that charring will build up inside gluing systems, including the hoses. Use of high quality hot melt glue will help to reduce the char build up. Here at Adhesive and Packaging Systems, we want to help you get the most out of your hot melt system as possible. Here are a few tips to avoid charring inside of your systems.

Keep the glue itself and the gluing unit free of debris

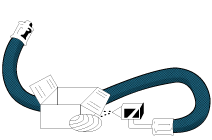

When something gets into the hot glue and moves through the system, it can leave residue in a hot glue hose. If you don’t catch the charring quickly, it can be a real issue, creating blockages in the hoses and glue guns. Adding an Auto-Loader into your operations is a great way to reduce debris getting into the gluing unit. It also has a filter to help remove any debris residue that might be on the glue.

Put machines on a routine maintenance schedule

Keeping the glue and the outside of the unit clean is important, but there’s more to keeping a hot melt system free of debris than just that. It is imperative to clean the inside of the unit as well. Flushing the unit regularly helps to ensure that debris and unintended materials don’t build up inside the unit.

Checking and replacing tank filters on a regular basis can help to improve the way the system functions, and to reduce the likelihood of charring inside the hot melt systems. It may also be beneficial to include hot melt hoses in that maintenance schedule. Look for areas of concern on the hose or dysfunction in the nozzle or leaky fittings, and replace as soon as possible.

For this type of maintenance, we recommend that machines are flushed, and filters monitored or replaced every three months.

Use a setback

A temperature setback allows the glue unit to transition into standby when it is not actively in use. Using a setback helps to preserve the glue in the tank and lessens the likelihood that it will degrade. With this type of system in place the temperature in the gluing unit is gradually allowed to decrease without requiring that someone is there to make it happen.

Ensure that piston pump units get enough clean air

It is important that piston pump units get adequate clean air as they run to avoid debris or and won’t allow to oil degrade the pump. Clean air allows the pump to cycle appropriately and reduces the risk of charring.

Don’t exceed the recommended temperatures

While some believe that increasing the temperature inside a tank will lead the adhesive to melt more quickly, we have found that this is not true. Instead, it can decrease the life of the adhesive, as well as the life of the unit. Heating the unit temperature above what the manufacturer recommends also increases the chance of char inside the system, which, as noted above, can wreak havoc on productivity and affect the overall life of the system and the glue itself. Keeping the readings down to the lowest possible temperature that still allows you to keep up with the dispensing demand will reduce the amount of char that builds up.

Extend the life of your hot melt glue systems

Implementing these tips can help you to extend the life of your hot melt glue systems; by keeping your machines clean and free of char, you may even see an increase in productivity because you’re not dealing with production shut-downs due to poor quality adhesion of glue or clogs within the machine.

At Adhesive and Packaging Systems, our first priority is providing high quality hot melt glue and appropriate glue systems that meet your needs. We offer a wide range of gluing machines, adhesives and parts to help you succeed. If you are in the market to replace hoses, nozzles or other components as part of a maintenance interval, or have other concerns, reach out to us and we will be in touch.